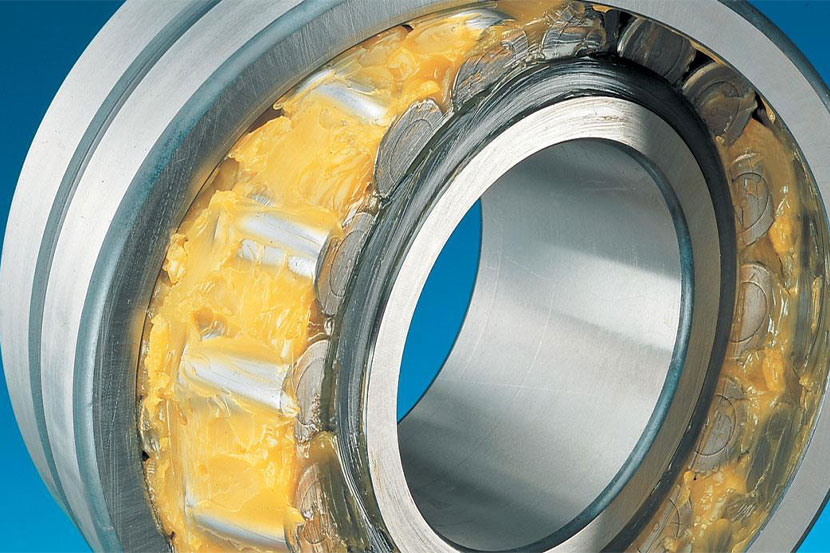

High performance lubricating oil (grease) to ensure longer service life of bearings

Bearings (including ball bearings, roller bearings, and other bearings in critical applications) require the use of high-quality lubricating oil and grease to ensure smooth operation. High performance lubricating oil (grease) can provide excellent lubrication effect and consistent viscosity, so that bearings can operate smoothly in heavy load and extreme temperature conditions, difficult to access positions, or critical equipment.

This high-performance bearing lubricating oil (grease) is suitable for the following important equipment/devices:

- Cars, trucks, and heavy-duty vehicles

- Corrugated roller

- windmill

- Oven

- Conveyor belt

- Fan

Hank high-performance lubricating oil (grease) is specifically designed to meet the needs of the above appliances during their service life.

Meet the special needs of sintered bearings

Sintered bearings are suitable for:

- Working conditions that require lower noise levels

- Variable load condition

- Working conditions with very small available clearances

This type of bearing is composed of compressed metal powder, and its pores are impregnated with lubricating oil. This type of impregnated lubricating oil can ensure that the bearings are in a lubricated state for life.

Whether used in metal, ceramic sintered bearings, or polymer based sintered bearings, Hank high-performance lubricants (greases) can maintain viscosity and lubrication performance in high-temperature and high-pressure environments, consistently outperforming hydrocarbon based lubricants (greases).

Numerous advantages

When used in ordinary bearings and sintered bearings, Hank synthetic grease and lubricating oil can exhibit long-term lubrication performance and reduce the frequency of re lubrication. Reducing maintenance frequency not only reduces operational costs, but also minimizes the generation of waste and its impact on the environment.

When Hank high-performance lubricating oil (grease) is used for ordinary bearings and sintered bearings, it can demonstrate:

- Excellent film forming ability: the lubricating oil forms a thick boundary layer, which can reduce wear.

- Outstanding antioxidant properties: When used in combination with advanced high-efficiency polytetrafluoroethylene (PTFE) thickeners, Hank lubricating oil will not oxidize, become viscous with increasing service life, and will not be damaged by shear force.

- Outstanding temperature resistance: Lubricating oil (grease) will not fail even when applied to high-temperature motors (operating temperature range: -75 ℃ to 350 ℃ [-103 ℉ to 662 ℉]).

- Excellent stability: Hank lubricating oil (grease) is waterproof, non flammable, and does not have chemical activity.

- Lifetime lubrication effect: Generally, there is no need to supplement lubrication to the bearings during the service life of the lubricating oil.

- Corrosion resistance: It has corrosion resistance and rust resistance during storage and in humid environments.